TECHNOLOGY > RFT

ROBERTS FLEX TECHNOLOGY (RFT)

|

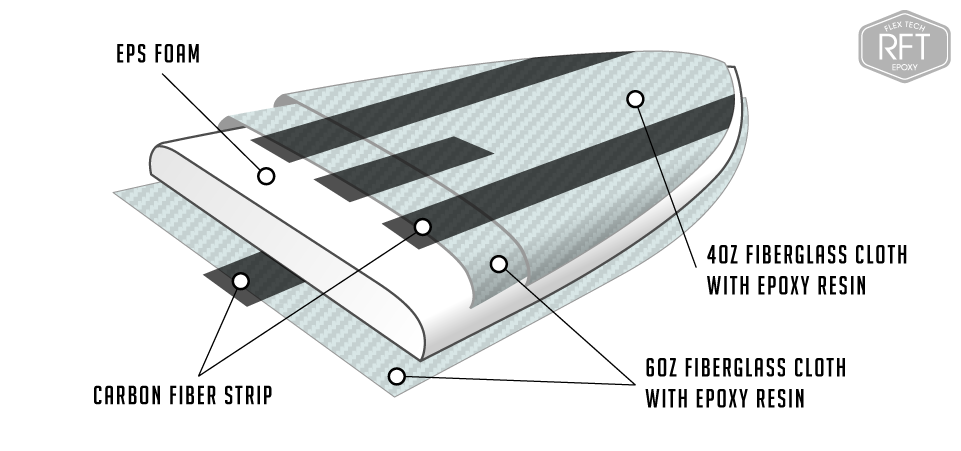

Roberts Flex Technology uses stringerless EPS blanks,epoxy resin, fiberglass and strategically placed carbon strips. RFT construction is designed for controlled flex based on the size of board as well as the rider’s weight and needs. For the optimum sweet spot and flex, we vary the width and placement of the carbon strips and use special layering of S-cloth on the rails and in patches on the board. These components work in conjunction to create a board that’s very light, strong and reactive.

RFT constructed boards start with stringerless EPS blanks. Glassing consists of the highest quality epoxy resins and fiberglass. Our standard glassing schedule for RFT stock or custom boards is a layer of 4oz and a layer of 6oz fiberglass on the deck and a 6oz layer on the bottom. Layers of S-cloth are placed on the rails and in specifically placed patches on the deck for strength and to control flex. A single strip of aircraft grade carbon is glassed down the center of the bottom and two are glassed running down the deck evenly spaced from the center to add strength and control flex as well. RFT construction may take a little longer to manufacturer than PU/PE since curing and sanding can be more involved. Options include: bio resin, change in glassing schedule for strength and to adjust flex |