TECHNOLOGY > RET

ROBERTS EPOXY TECHNOLOGY (RET)

|

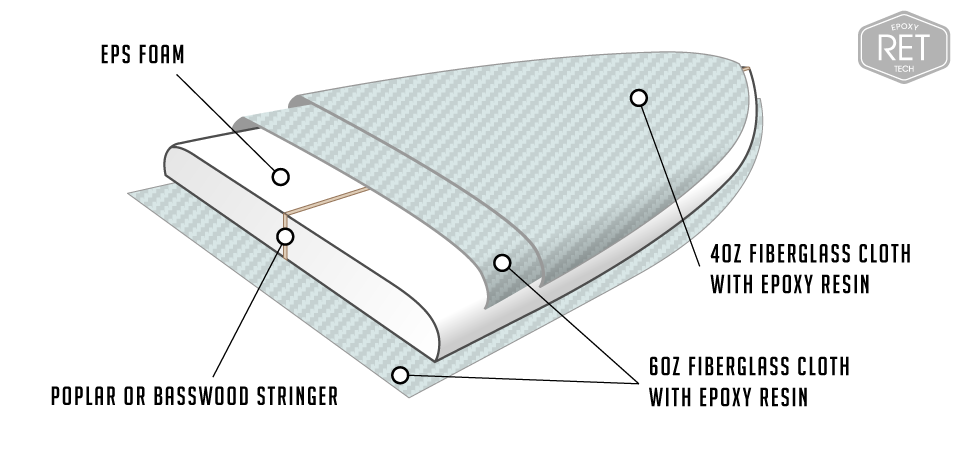

Roberts Epoxy Technology (RET) uses stringered EPS blanks with epoxy resin and fiberglass. RET construction is lighter, stronger, and feels livelier than PU/PE. The reduction in weight and a tighter flex pattern gives RET a nimble feel that makes the board easier to change directions and push through maneuvers. In particular RET is a great option for small wave boards since every ounce of extra speed you can get in small surf is a bonus. And for beginners or bigger guys having a lighter stronger board is a real advantage for performance.

Our standard RET constructed boards use Marko, US or Procam blanks with poplar or basswood stringers. Glassing consists of the highest quality epoxy resins and fiberglass. Our standard glassing schedule for RET stock or custom boards is a layer of 4oz and a layer of 6oz fiberglass on the deck and a 6oz layer on the bottom. RET construction may take a little longer to manufacturer than PU/PE since curing and sanding can be more involved. Options include: bio resin, change in glassing schedule for strength or weight, carbon tail strips, carbon strips down the stringer(s), or a wider stringer |