TECHNOLOGY > RFT-TDD

ROBERTS FLEX TECHNOLOGY TAPERED DUAL DENSITY (RFT-TDD)

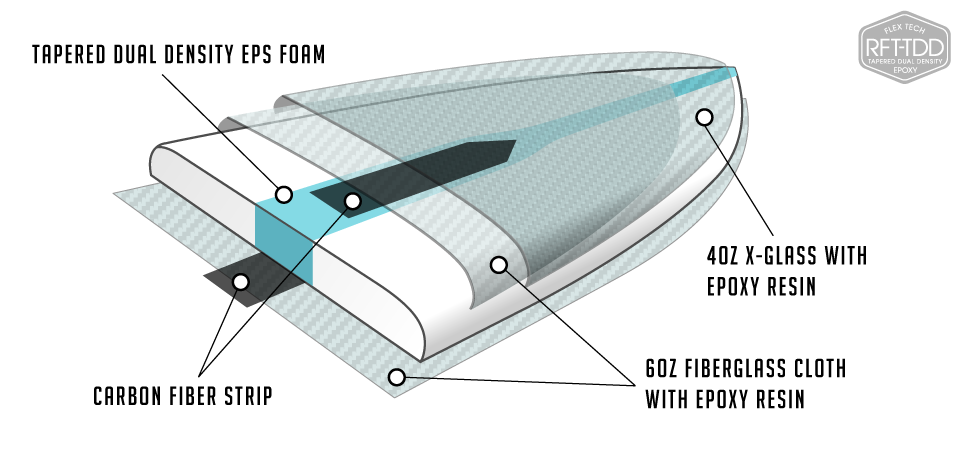

Roberts Flex Technology Tapered Dual Density (RFT-TDD) uses stringerless Tapered Dual Density EPS blanks, epoxy resin, fiberglass, and strategically placed carbon strips. The RFT-TDD blanks are a proprietary design with an area of denser foam through the center of the blank tapering at the nose and tail. The high density foam gives the board a more solid feeling due to the dampening of vibration as well as providing a stronger deck under your front foot. Tapering the denser foam at the nose and tail allows the board to flex where it needs to so that you have plenty of drive and stability through turns.

Like all of our RFT constructions RFT-TDD boards are very light, strong and reactive. RFT-TDD constructed boards start with our TDD EPS blanks. Glassing consists of the highest quality epoxy resins and fiberglass. Our standard glassing schedule for RFT-TDD stock or custom boards is a layer of 4oz X-Glass fiberglass and a layer of 6oz fiberglass on the deck. In the center of the deck under the front foot area, a short length of wide carbon stripping is used to isolate flex and add more strength where the board needs it most. Layers of S cloth are strips and patches are specifically placed on the deck for strength and to control flex. A layer of 6oz fiberglass is used on the bottom as well as a single strip of aircraft grade carbon that is glassed down the center of the bottom ending above the center fin box to allow flex in the tail area.

Like all of our RFT constructions RFT-TDD boards are very light, strong and reactive. RFT-TDD constructed boards start with our TDD EPS blanks. Glassing consists of the highest quality epoxy resins and fiberglass. Our standard glassing schedule for RFT-TDD stock or custom boards is a layer of 4oz X-Glass fiberglass and a layer of 6oz fiberglass on the deck. In the center of the deck under the front foot area, a short length of wide carbon stripping is used to isolate flex and add more strength where the board needs it most. Layers of S cloth are strips and patches are specifically placed on the deck for strength and to control flex. A layer of 6oz fiberglass is used on the bottom as well as a single strip of aircraft grade carbon that is glassed down the center of the bottom ending above the center fin box to allow flex in the tail area.